Category Archives: The Fashion & Craft Industries

Wool Fabrics Made in Yorkshire! A Visit to Fabworks

Posted in Fabric, Sustainable Sewing, The Fashion & Craft Industries

Tagged birdseye weave, fabworks, fabworks mill shop, fabworks online, heart of huddersfield, herringbone fabric, industrial heritage, made in huddersfield, made in yorkshire, marled melton fabric, melton fabric, tailoring fabric, traditional wool fabric, Wendy Ward, wool fabric uk, wool industry, yorkshire fabric, yorkshire textiles

Making Fabric in the UK – A Visit to Discovery Knitting in Leicester

Posted in Sustainable Sewing, The Fashion & Craft Industries

Tagged a beginners guide to sewing with knitted fabrics, Beginner's Guide to Sewing With Knitted Fabrics, beginners guide to sewing knits, british made fabric, discovery knitting, home textile industry, how is fabric made, how is jersey made, industrial knitting, knitted fabric, knitted fabric manufacturer, made in the uk, making fabric, sewing knitted fabrics, uk made fabric, uk textile industry, where to buy knitted fabrics

A Visit to Masson Mills Working Museum

Posted in Sustainable Sewing, The Fashion & Craft Industries

Tagged arkwrights mill, cotton mill, cotton weaving, derwent valley mills, how is cotton made, industrial heritage, industrial revolution, inside a cotton mill, masson mills, northern industry, richard arkwright, victorian cotton mill, Wendy Ward, working cotton mill, working museum

Does Sustainable Sewing Lead to Ethical Fashion?

Posted in Sustainable Sewing, The Fashion & Craft Industries

Tagged clean clothes campaign, ethical fashion, fashion revolution, how are clothes made, informed consumer, knowledge is power, labour behind the label, make a difference, slow fashion, sustainable fashion, Sustainable Sewing, uk fashion industry, Wendy Ward, what is ethical fashion, what is slow fashion, what is sustainable fashion, working in the fashion industry

Zero Waste Sewing

Posted in Sustainable Sewing, The Fashion & Craft Industries

Tagged cut my cote, holly mcquillan, julian roberts, medieval tailor's assistant, RSA, slave to fashion, stash busing projects, stash busting, sustainable fashion, Sustainable Sewing, timo rissanen, use your stash, zero waste, zero waste fashion, zero waste fashion design, zero waste sewing

Slow Fashion October – Introductions

Are you taking part in this year’s “Slow Fashion October“? It’s organised by Karen Templer of Fringe Association and I remember seeing lots of posts on Instagram from last year’s event and thinking “That’s something I want to take part in”.

Each week in October will have a different theme and last week’s was “Introductions”. Go and have a read of Karen’s post, it’s a great introduction to the project and why it’s important. She’s included some really thought-provoking links. OK, I’m a little late to the party, but better late than never, so here’s my introduction post.

Karen asks us to consider these questions:

- Who are you, and what does slow fashion mean to you?

- What got you started thinking about it — people, books, films, etc.

- Are your concerns environmental, humanitarian, financial?

- Most important: How does your thinking factor into your life and closet?

- Also, any special plans or projects for Slotober, and what are you hoping to get out of it?

My Slow Fashion October Introduction

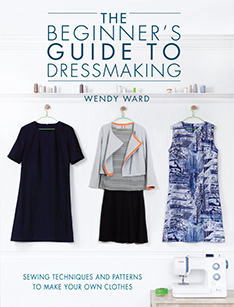

I am a clothing pattern designer, a maker, a teacher and a sewing book author. I’ve been doing this since 2007 and my days are occupied with how clothes are made. Before 2007 I worked in the fashion industry in the UK for 7 years. I worked for the 2 extremes of the industry; at the fast fashion, disposable end of the industry I designed boyswear for Matalan at the start of my career in 2000, then in 2001 I became the product development manager for a newly established organic cotton brand called Gossypium. This gave me a great insight into what needs to change and what is actually possible in the clothing industry.

While working at Matalan, I literally churned out designs; 80 – 100 new designs a year, mainly “inspired by” (aka copying) garments that buyers bought on “inspirational shopping” trips around Europe and the US. I had no idea how and where any of these garments I was creating were being made (and nor did the majority of people I worked with, including the buyers, I know because I asked the question). To say it was a depressing job as a graduate fresh out of design school would be an understatement. It was, however, an eye-opening reality check and I lasted 7 months.

At Gossypium I worked with cotton farmers, textile specialists, garment makers and home weavers in the UK and in India. I was hands-on, I got to talk to people about ideas they had about how to make clothes, I got to play around with fabric to create garments rather than just draw imaginary garments on a computer screen and I got to sit beside machinists while they made them. The brand was (and still is) a success; within a few years I saw my designs that I knew the complete history of stocked in Harrods. I loved that job and am incredibly proud of what I did there.

A development sample from my MA

A development sample from my MA

After I left Gosspium I pursued a different but related route and undertook an MA on ways to recycle textiles. That work is ongoing and even though I haven’t really picked it up in a while I get involved in projects that use recycled textiles wherever I can; I’ve taken part in Portia Lawrie’s The Refashioners event for the past 2 years and right now am working on a collaborative project with a local Brighton charity on recycling.

I love the process of making and it makes me incredibly sad to see how detached we’ve become as a society from the process. I think our inherent creativity and ability to make things are fundamental parts of what makes us human and what can help to keep us happy. A dangerous knock-on effect of this deskilling makes it easier to ignore the conditions around how things are made and I feel it’s the same in food; meat comes packaged on the supermarket counter with no trace of its origins in coming from an animal and how many people would be willing to visit an abattoir to see the real story behind their roast dinner? That’s why I don’t eat meat.

I don’t often buy ready-to-wear clothing any more (mainly as I can make most things myself), but when I do I really consider it; I do my research and find exactly the thing I want and I wait until I can afford it. I buy quality that I know will last, will maybe have a re-sale value if I don’t want to keep it and ideally is made in the UK, but if not, then made by a responsible manufacturer. I very rarely shop on the high street and I try really hard to practice what I preach.

I’m starting to apply these same principles to my fabric shopping. I’m not lured by cheap, I like quality natural fibres, I love organic fabric and I try to buy from fabric shops who have a direct relationship with their suppliers rather than just buying from faceless wholesalers and middle men. I’m also looking at ways to produce my own fabric, obviously not from scratch, but sourcing high quality organic fabrics that I then print, dye and decorate myself. That may become my focus for Slotober.

I’ve written before about applying these principles to your sewing, rather than sewing something because it was a free pattern with a magazine and you’ve seen lots of other people making it online, stop for a minute and think – does that style really work for me? Do I need another of those garments? Am I going to rush this project just so that I can join in with the other people who have made this pattern online? Focus on what you want to sew, why you want to sew it, how much you’re going to wear the finished item and enjoying the process. I call this “Thoughtful Sewing”.

My slow fashion concerns are environmental, humanitarian and financial; using natural fibres, organic farming methods, water based inks and low impact dyes isn’t impossible. People with a skill and a trade wherever in the world they live deserve the dignity of working in a safe environment with access to trade unions, time off and earning a fair wage which is a reflection of their time and skill. The shirt/dress/jeans on your body are not worth sacrificing those things for.

I don’t have any special plans that I wouldn’t normally be doing for Slow Fashion October (other than the fabric work mentioned previously), but I am looking forward to being inspired by what everyone else is doing and how everyone else deals with these challenging issues at @slowfashionoctober on instagram and the #slowfashionoctober hashtag.

I’ve written more about similar subjects to this here.

Should Pattern Designers Know How to Draft and Grade Patterns?

The view on my computer screen has looked a lot like this for the last few days

I got all the graded patterns back for my new book last week and am currently in the process of getting them ready to go to print.

I know how to grade patterns, but I choose not to do it myself because:

- I don’t have the right software to do it digitally,

- manual grading takes forever,

- it can be quite a boring job and I’d rather be doing other more creative tasks!

When patterns come back from the graders I get a full size set on card to use in classes and a digital set that can go to print.

I always find that the digital patterns require a bit of tweaking, just a bit, but some truing up here and there. Because I can draft and grade patterns myself and have been doing it for a long time, I know what to look for. But I started thinking while doing this job today; I wonder if all pattern designers do this, or for that matter, would even know to check their grading?

I know of pattern designers who don’t even draft their own patterns, so presumably they have no idea how to grade a pattern. I also see people who appear to have only just started to sew releasing their own patterns. How are these patterns checked and trued?

Now, I’m not saying I’m a saint and know all there is to know about pattern drafting and grading, in fact I’m happy to always be learning. But, I do know the importance of trued pattern pieces, carefully placed and matched notches, and I’ve gained that knowledge through years of practical experience.

Unlike sewing, pattern cutting is an exact science; it needs to be right. If the pattern’s out, the resulting garment won’t sew together easily and won’t look right. It’s like baking a cake; you can’t change the quantity of flour without changing the quantity of sugar, eggs and butter (I’m no cook, but I do grasp a few basics!)

But is this ok? We can’t all be brilliant at everything. Why shouldn’t a designer get someone else to draft their patterns and/or do their grading without feeling the need to check any of it? My feeling is that it’s how connected that designer wants to be to their customer. If you want to ask a question about a pattern, think you might even have spotted a mistake in a pattern or want to see a sew-along or pattern hack for a particular pattern, what’s the point in asking a pattern designer who has no idea how it was created in the first place?

What’s your experience? I’d love to know.

Posted in Books by Wendy, Sewing Patterns by Wendy, The Fashion & Craft Industries

Tagged beginner sewing patterns, beginners guide to skirts, easy sewing patterns, indie pattern designers, indie patterns, indie sewing patterns, pattern designers, pattern grading, sewing pattern designers, sewing patterns, skirt sewing patterns, Wendy Ward

The Quote That I Live By

I’m going to tell you a story about this page from one of those daily calendars.

Fashion Revolution Week happening at the moment and this post I wrote are what got me thinking about it.

Tuesday 27th February 2001 was quite a momentous time for me; it was the week I would leave my job as the sole boyswear designer for Matalan (a big corporate business which provided a career with a pension and career progression routes, etc), where I produced designs like this

at a rate of 80+ pieces per year with no idea where my designs were actually made. To work for Gossypium (a brand new business that would consist of just me and the two founders)

where I had time to research, test and develop my designs (both in the UK and in India working with our manufacturers) with the result being our first yoga wear collection being stocked in Harrods and Gossypium still selling clothes I designed 15 years later.

I’ve kept this page in subsequent diaries for the last 15 years as a reminder of what I did and it’s become a guide for how I try to live my life.

To give up without even trying is the thing that is almost guaranteed to frustrate me about people; I can put up with and try to make excuses for a lot of behaviours but not being willing to try, no, I just can’t stand it.

I have no idea who this quote is attributable to (if anyone), but I think it’s very relevant on Fashion Revolution day, as an argument that I regularly hear along the lines of “What difference can I make?” is the “But if we stop buying from there then they won’t have any jobs at all and that will be much worse”. I find that a profoundly lazy argument. We can make a difference, companies like Gossypium and People Tree among many others have proved that and how did they manage it? Because they TRY and often need to try some more and then try again.

It saddens me that lots of people have their priorities all wrong; that they consider the most important things to spend money on are houses, cars, holidays, electrical gadgets and cheap processed food (mostly in that order in the UK). If someone can pay £000’s per month on that stuff you’re not telling me they can’t spend a bit more on better produced clothing. If you went to a restaurant and were given a piece of meat on your plate and the waiter wasn’t able to tell you what animal it had come from, how it had been cooked and when, I’ll bet you wouldn’t dream of eating it.

Make a difference, just try it and see.

Fashion Revolution Week Starts on Monday

Image from fashionrevolution.org

Image from fashionrevolution.org

Did you know it’s Fashion Revolution week next week from Monday 18th to Sunday 24th April?

No idea what I’m talking about? It’s happened every year since 24th April 2013, the day of the devastating, but preventable collapse of the Rana Plaza building in Dhaka, Bangladesh which housed a garment making factory used by many of the clothing brands on our high street. 1134 people were killed in that incident and over 2500 more injured. All in the name of feeding the West’s appetite for more and more and cheaper and cheaper clothing.

The collapsed Rana Plaza building – photo from bbc.co.uk

The collapsed Rana Plaza building – photo from bbc.co.uk

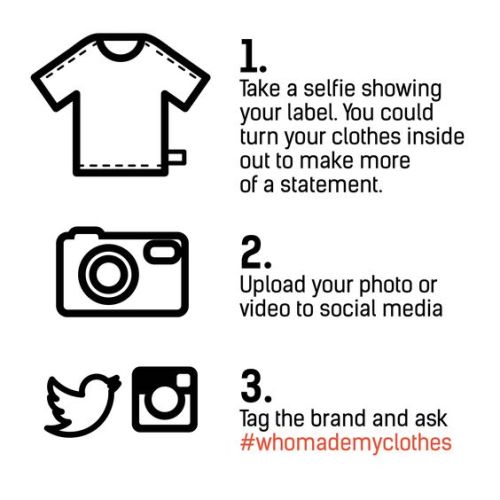

In response, Fashionrevolution.org started a simple campaign; for ordinary consumers of clothes like you and me to look at the label inside the clothes we’re wearing and to ask the brand on the label just one question: “Who Made My Clothes?”

Image from fashionrevolution.org

The campaign gains momentum every year online through people taking selfies, tagging the brands on their labels and asking the “Who Made My Clothes?” question. Just search the hashtags #fashrev and #whomademyclothes on Twitter and Instagram and see what comes up.

I think it’s an ingeniously simple idea as it not only encourages brands to be more transparent about their manufacturing processes, but it also prompts us consumers to actually think about the question ourselves; arguably the more important effect in my humble opinion, as big business responds to demand and that demand must come from us.

Image from fashionrevolution.org

Image from fashionrevolution.org

This subject is close to my heart as anyone that knows me or has been a regular reader of my blog will know. In my early career in the fashion industry I spent 4 years working for a company called Gossypium who produce clothing made from organic fair trade cotton.

When I worked with Gossypium everything was made in India using Indian grown organic cotton and I was lucky enough to visit many of the people who manufactured cloth and garments for us.

Me looking like a giant in a small village in Tirupur in southern India where villagers could earn a decent living hand weaving organic cotton fabrics in their homes. (2003)

Me looking like a giant in a small village in Tirupur in southern India where villagers could earn a decent living hand weaving organic cotton fabrics in their homes. (2003)

My designs for Gossypium were even stocked in Harrods. I’ve seen with my own eyes what a difference responsible sourcing and manufacturing can make and that even though it can be challenging, it’s not impossible.

Image from fashionrevolution.org

Image from fashionrevolution.org

This job was in stark contrast to the one I did before, where as a fresh naive graduate I became the sole boyswear designer at Matalan. A role where I found myself literally churning out designs working 60 hour weeks and had no contact at all with anyone on the manufacturing side of the business (at that time it seemed to me that no-one at head office knew exactly where Matalan’s clothes were manufactured).

Before all of that, while still doing my degree, the subject of my dissertation was sustainable textiles. (Quite a revolutionary thing to do on a fashion degree in the late 90’s!)

“It’s sad that something we love to do: making clothes, can be used to exploit people and environments to satisfy the greed of others.” Tweet this.

Now that I’m a maker, teaching and encouraging others to make, we can say “I Made My Clothes” which is brilliant, but now we need to start asking “Who Made My Cloth?”

Organic fair trade fabrics available by the metre to home dressmakers can be hard to find and seem costly, for the same reasons that sustainably and fairly made clothes cost more, but just like consumers of ready-to-wear clothing we have a responsibility to try our best where we can. In this spirit, I have included a sample garment in my new book which is made from hand dyed organic denim, it’s a stunningly beautiful garment and I’m hoping to use much more fabric like this in future.

To find out more about using sustainable fabrics in your dressmaking, I wrote this post almost 3 years ago detailing where you can buy organic fabrics (which I try to keep up to date) and have a read of my inspiring interview with Charlie Ross of Offset Wharehouse that I did last year for Love Sewing magazine.

Want to know more and do something?

Start by having a look at the Fashion Revolution website, there are some brilliant free resources to download (such as the poster above for your selfies) and to print and share online alongside links to all of their work. They also have an excellent resources page which links to news articles, websites, books and more about the subject, it’s here: http://fashionrevolution.org/resources/further-reading/

Then, watch the film “The True Cost”.

If you’re local to Brighton, there is a local Brighton Fashion Revolution group on Facebook who are organising lots of events you can get involved with next week, including a screening of The True Cost film with a Q&A where you will find the knowledgeable Siobhan of Brighton’s Fair shop on the panel. I’m sure there are similar local groups all over the world.

If you want to read all the posts I’ve written on this subject, here they are:

- When Are Clothes Too Expensive?

- What Is It Really Like To Work In The Fashion Industry?

- Where To Buy Organic Fabrics

- Why Use Ethical Fabrics In Your Dressmaking?

“Knowledge is power; with knowledge you can take action and make decisions that you can live with. #fashrev” Tweet this.

So, this has turned into a bit of an epic post, but it’s an important subject that we need to take seriously. I hope you’ve found it both inspiring and useful, I’d love to hear your thoughts on the subject….

I’ll leave the final word to Dame Viv…..